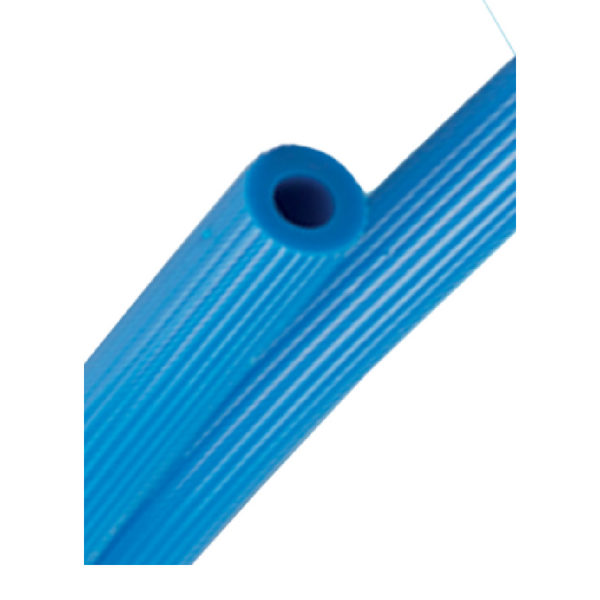

Polyinject Hose

Polyinject Hose

Single channel reinjectable hose

Properties

- Sealing of construction & butt joint

- Can be used for multi grouting

Description

Polyinject Hose is a single-channel reinjectable injection hose that is used as regular joint filling for the sealing of construction and butt joints. It can be used for multi-grouting in conjunction with the injection materials that have been tested for applicability. Polyinject Hose consists of a low-foamed PVC jacket with a fluted surface. the injection material is applied into the joint to be sealed via small slots in the hose jacket. Positioning and shape of the slots prevent cement slurry intruding into the injection channel.

TDS For Polyinject Hose

- Step by Step

Surface requirements

Polyinject Hose is fixed to the level concrete surface that has been cleared of any loose matter and cement slurry. any ice films must be melted prior to laying, any ponding water that has collected must be blown off the surface (oil-free compressed air). The surface must be firm and free of any sharp-edged differences in height (landing). The concrete on both sides of the joint have a high water impermeability.

Installation

Polyinject Hose is fixed with plastic clips or metal nail clamps. The plastic clip is driven into bore holes of 8 mm diameter. the most simple fixing method is to use metal clamps that can be nailed or closed. The fixing points should be spaced every 10 cm. Spacing between the fixing points should not exceed 15 cm to ensure that the injection hose is retained sufficiently for concreting. Contact between the individual hose sections must be avoided in order to prevent the hoses from grouting each other. as a rule the air-bleed ends are led out of the construction at a right angle. They may be connected in protective boxes that are fixed to the reinforcement. or they are fixed to the formwork panel spigots. permeability, accessibility, markings, if applicable, and the protected position of the hose ends (air-bleed ends) must be safeguarded for subsequent grouting.

Injection

Accessible joint sections must be checked for imperfections etc. prior to injecting the hose sections. detected imperfections must be professionally sealed prior to injection. Injection work should be carried out at the earliest after the hydratisation process has abated and with the construction joint under full stress. Injection work on connected structural components is carried out in sections, beginning on one side. horizontally positioned hoses are injected from the bottom up. To fill the injection hose, one side of the hose is first filled with injection material until the material pours out at the other end free of bubbles. then this hose end is sealed. after the hose end is sealed, the injection pressure is slowly increased to enable the injection material to pour out of the slots evenly into the joint. If Polyinject Rubber acrylate gel or Polyinject Cement is used, multi-grouting is possible if the hose is sufficiently flushed with water immediately after injection. pressure-less rinsing through of the injection hose (the grouting end sealed previously must now be opened) must be carried out before the pot life of the injection material runs out. the information required for this can be found in the data sheets for the individual injection materials. The 2-component injection pump, that is equipped with an flushing detergent pump, is recommended for injecting acrylate gel.