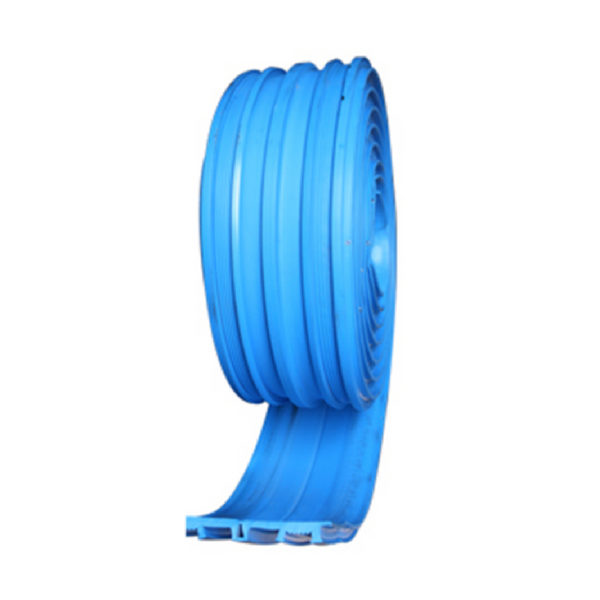

Polystop

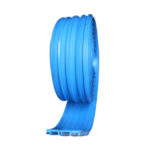

Internal and external PVC waterstop

Properties

- High tensile strength & elongation

- Unique design. Specific ribbed profile for effective water sealing performance

- Brass eyelets on edge flanges for tying with steel reinforcements (Internal profiles)

- Heat weldable

- Non toxic. Suitable for use in contact withpotable water

- Prefabricated intersections

- Excellent chemical resistance

- Non-staining. Will not discolor concrete or produce electrolytic action

Description

Polystop water stops are high grade poly Vinyl chloride (PVC) resin extrusions that are plasticized and stabilized to offer long life performance in concrete structures against water leakages. The cross section configuration features a multi rib design for an effective grip and tenacious anchor to the concrete and a flexible, hollow center bulb to accommodate moderate expansion and contraction in the concrete. Polystop waterstops are manufactured to meet the most stringent performance specifications and are resistant to abrasion and chemicals.

TDS for Polystop

- Step by Step

Surface Preparation

Surface of the Polystop shall be cleaned of all dirt and cement laitance which can affect the water tight seal with the concrete.

Application

Fixing internally:

Internal and centrally placed waterstops are positioned within the concrete where the centerline of the waterstop is aligned with the centre of the joint. Such waterstops functions as a watertight diaphragm wall against any water leakage. For a proper placement of the waterstop, split formwork is recommended when installing in slab-to-slab, slab-to-wall and wall-towall joints. The waterstop is then tied with wires trough the eyelets provided at the end flanges to the reinforcement. This will ensure that the waterstop firmly held in position and is not misaligned or fold during the concrete pour. one half of the waterstop has to be positioned within the first pour and the other half projecting into the second pour. A tight fit between the waterstop and the form is also necessary to prevent excessive leakage of concrete paste, which could lead to honeycombing of the concrete.

Fixing externally:

The externally placed waterstop is installed prior to pouring of concrete. The external expansion joint profile is usually loosely laid on top of the compacted grade or mudslab. The stop end form works are then fixed on top of the waterstop. The waterstop can either be nailed or glued into position to avoid displacements during the concrete pour. The external construction joint profile is glued or nailed on to the vertical shutter. The waterstop is so positioned that only the ribbed side is embedded into the concrete.

Jointing:

A fully continuous water stop network must be formed throughout. at bends and additional joints, factory welded junctions are to be used when jointing with the placed water stops. Field buttsplices shall be heat fused welded using an appropriate welding knife of voltage ranging between 220-240V(ideally with thermostatically controlled). The edge of the water stop shall be cut with a knife to get an even and sharp finish and aligned in a specially designed fixing jig.the edges will then be positioned in the jig in such fashion that at least 25mm of water stop protrudes from the jig. Place the welding knife in between the two ends, and when the pVc starts melting (>140°c), beads will start forming around the section. remove the welding

knife and press both the ends firmly against each other to form a neat buttsplice. press the joints against each other for sometime till the pVc cools and forms a strong fusion welded joint.