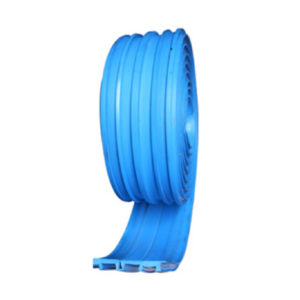

Bitutape 150 PVC

Anti corrosive pipe wrapping tape

Properties

- Easy to apply

- Excellent adhesion

- High strength

- Flexibility

- Resistance to Acid & Alkali

- Excellent impact resistance

Description

Bitutape 150 PVC is a high performance anti-corrosive pipe wrapping tape designed for use on buried pipeline, pipe joints, fittings and tie bars where impact or stress is low.

TDS for Bitutape 150 PVC

- Step by Step

Surface Preparation

Remove any dirt, oil, grease, rust by suitable methods. remove any metal burrs or weld spatter. The minimum requirement for surface preparation of pipe/steel surface is by mechanical/power wire brushing to remove any rust scales. Grit blasting can also be done in heavily contaminated areas.

Primer

Bitutape Primer* (solvent based bitumen primer) shall be used for priming the steel surface prior to the application of the wrapping tape. Stir the contents of the primer for 1-2 minutes to remove any sediment. Apply the primer with a brush or roller evenly to ensure complete sealing of all small undulations and imperfections, particularly around weld beats. Reseal the containers when not in use.

Wrapping

Application instructions are for guideline only and are subjected to alterations for specific project requirements. Wrapping should not commence until the primed surface has become touch dry. Apply strips of tape 100mm wide along the weld beads and press firmly. Peel back 150 to 300 mm of the release film and apply the tape, adhesive side, to the pipe. The angle of the tape must be such as to produce the specified overlap. Apply only sufficient tension to ensure good conformation avoiding air pockets and bridging. Ensure end lap area of at least 150 mm when splicing the tapes. Backfill with care. Use of a Bitustick R protection membrane is recommended to prevent any damage from backfilling. avoid use of rocky or agglomerated backfill.

General

Surface preparation, priming or wrapping should not take place when the substrate is wet. Do not carry out work when the surface temperature is less than 5°C. All sources of ignition must be extinguished or removed before carrying out priming operation. Adequate ventilation must also be ensured. Store the tapes at temperatures not exceeding 30°C and avoid excessive load stacking. During the wrapping application it is important to maintain an even tension whilst controlling the overlap to prevent air entrapment, which could lead to corrosion at a later stage. The tapes are best applied by machine, either hand powered for small runs or mechanically propelled for longer runs. Bitutape 150 PVC range of tapes is normally supplied in 10 m lengths. For machine wrapping these lengths are increased to suit the project and reduce the number of roll changes.