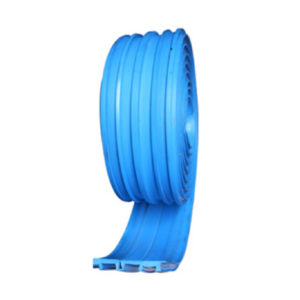

Polythane 50

Polythane 50

One part UV stable polyurethane based waterproofing coating

Properties

- Excellent UV resistance

- Good Abrasion resistant

- Excellent chemical resistance

- Ease of application. Single component

- High elastic recovery

- Good tensile strength

- Good resistance to ponded water

Description

Polythane 50 is a single component liquid applied elastomeric polyurethane based coating. It is designed to give long lasting, maintenance free and superior waterproofing protection for concrete and steel substrates. It is a u.V. stable coating and is specially formulated for external applications.

TDS For Polythane 50

- Step by Step

Surface Preparation

Concrete Surface:

Surface preparation plays a vital role in determining the durability of any coating. Therefore proper care should be taken while executing it. The concrete should be minimum 28 days cured before the coating is applied. The surface should be free from dust, dirt, curing compound, oil, etc. Clean the surface thoroughly to remove all loosely adhering particles and cement laitance. It is recommended to use a light mechanical grinder for cleaning. Cracks and pot holes should be repaired with suitable concrete repair system from the Polycrete* range and allow it to cure.

Steel Surface:

The substrate should be abraded and preferably shot blasted with grit or steel balls. Area where steel blasting is not practical, pretreatment must be carried out with premature descaling guns, rotary wire brushes or by flash scaling. The surface should be then cleaned with a strong solvent or a detergent to remove any grease or oil contamination. The cleaned surface must be coated as soon as possible before the formation of any rust or scale.

Primer

Apply Polyprime PU* as a primer @5 m²/L for 250 microns dry film thickness. The coating is applied when the primer is dry. However, in all circumstance, the coating has to be applied within 24hrs of the application of primer.

Mixing

Polythane 50 is single component but stirring of the pail is recommended prior to the application of the coating. This will remove any sediment which may occur during storage. the use of a slow speed drill and suitable paddle should be used in order to avoid the formation of air bubbles.

Application

Apply Polythane 50@ 0.6 lt/m² per coat. allow it to dry for at least 12 hrs prior to the application of the second coat. The second coat is to be applied at the same coverage rate. Two coats of polythane 50 will give a dry film thickness of 1mm. Allow Polythane 50 to cure for at least 3 days.

Protection

As a protective coating on concrete/render/plaster surfaces, the coating should be applied @0.75 lt/m²/coat for a DFT of 1mm in 2 coats.