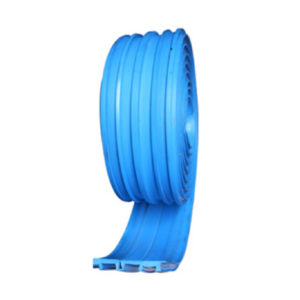

Polypur TC 20

Polypur TC 20

2 component UV stable, polyurethane car park deck coating

Properties

- Highly durable and UV stable

- Excellent abrasion resistance

- Good chemical resistance

- Can be applied on many different substrates and on cured epoxy systems

- Excellent surface finish with different colors

- Easy to apply

Description

Polypur TC 20 is a two component high quality UV stable polyurethane car park deck coating system. The coating provides a seamless, abrasion resistant floor coating system for both internal and external areas.

TDS For Polypur TC 20

- Step by Step

Surface preparation

The surface should be dry, free of any cement laitance, oil and grease, curing compound and any other contaminants, which may affect the bonding. Light mechanical scabbling, grit/captive blasting or grinding is recommended for cleaning the surface of such contaminants. New concrete surfaces should be 28 days old and the moisture content on the surface must be less than 5%. Refurbishment of existing or old floors must be done with a suitable repair mortar, in order to ensure that the bond between the old substrate and the new flooring system is very good. Surface irregularities and blow holes shall be repaired with Polypoxy BF* (Epoxy resin based blow hole filler and skimming mortar) or Ceresit RS 88* (cementitious repair mortar). Alternatively an epoxy resin based scratch coat can be used when repairing larger areas (> 0.5m2). The surface should be vacuumed after carrying out the necessary cleaning for removing the dust debris left over after the cleaning process.

Priming

Prime the prepared surface with Polyprime PU* @ 4-5m2/L. The coating is applied when the primer is dry. However, in all circumstances, the coating shall be applied within 24 hours of application of the primer. If the primer surface is left open for more than 24 hours, then a fresh coat of primer has to be re-applied. Broadcast Aggregate No. 3 on the primer whilst it is still wet @0.3 kg/m2. On ramp and turning areas, the aggregate shall be broadcasted @1.2-1.5 kg/m2. After the primer dries off brush away or vacuum out the excess aggregates.

Top coat

Polypur TC 20 shall be applied as the abrasion resistant top coat. This UV resistant coating is supplied in two pre-weighed packs (resin & hardener). Take a suitable container and pour the resin (A) into it. Add the hardener (B) into the resin and mix thoroughly with a slow speed drill with a proprietary paddle mixer for 2 -3 minutes, until a homogenous consistency is obtained. Work the mixer round the mixing pan to ensure it scrapes the side and bottom of the pail. Once the material is mixed immediately apply the coating with a roller or airless spray at a coverage rate of 5m2/L. If required apply a second coat at the same coverage rate and only after the first coat has dried off completely (24 hours). The coating will achieve its full mechanical properties after 7 days of cure, after which the floor can be subjected to heavy traffic. days of cure, after which the floor can be subjected to heavy traffic.