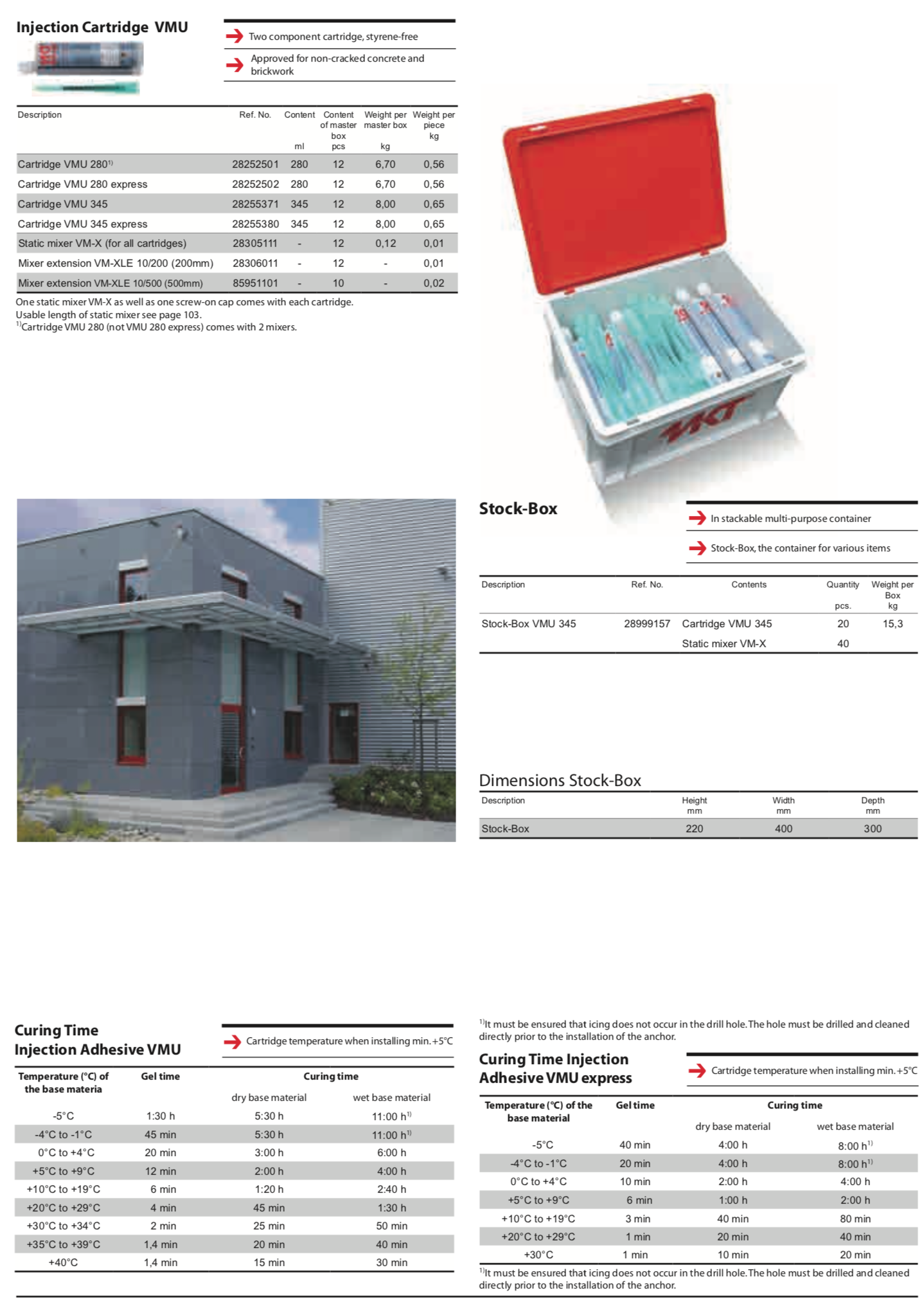

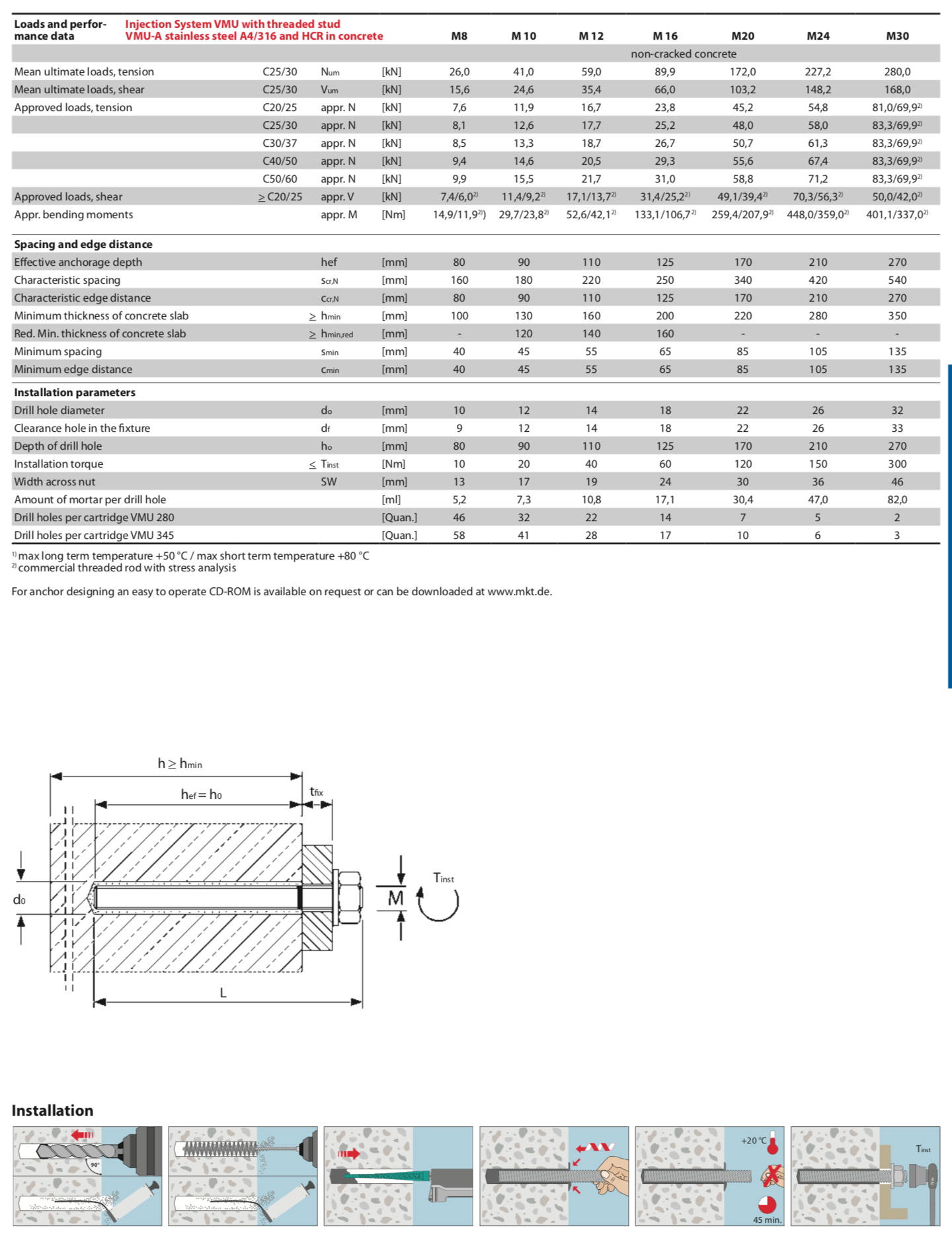

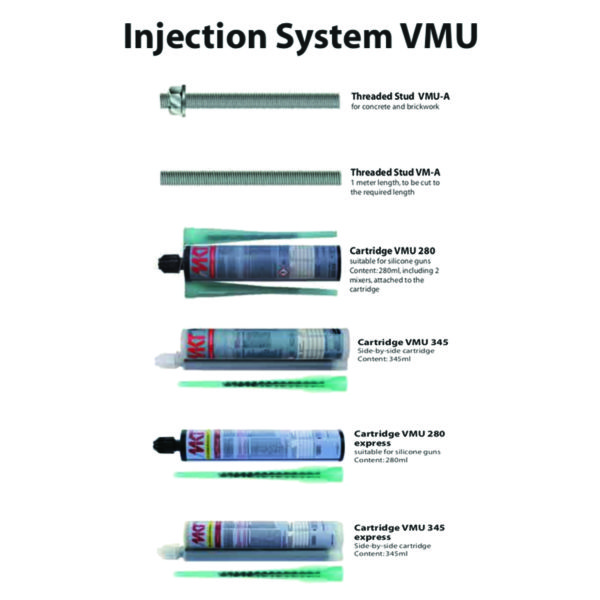

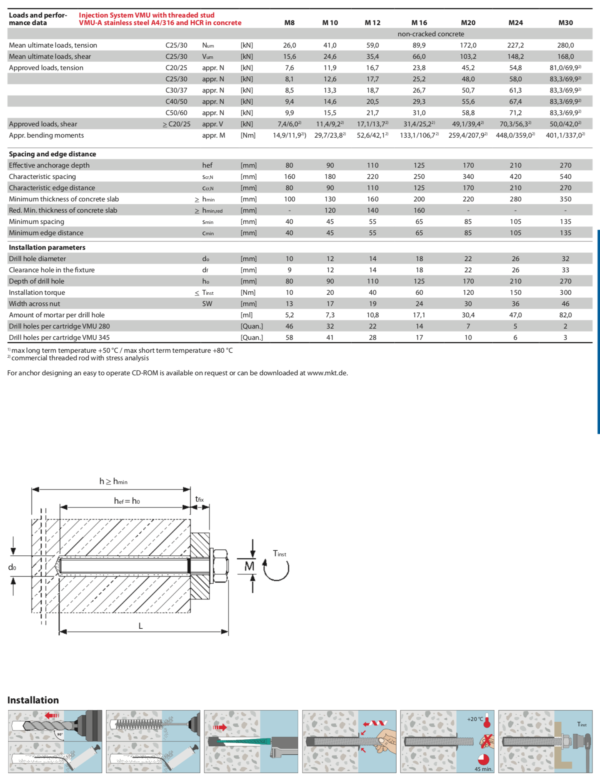

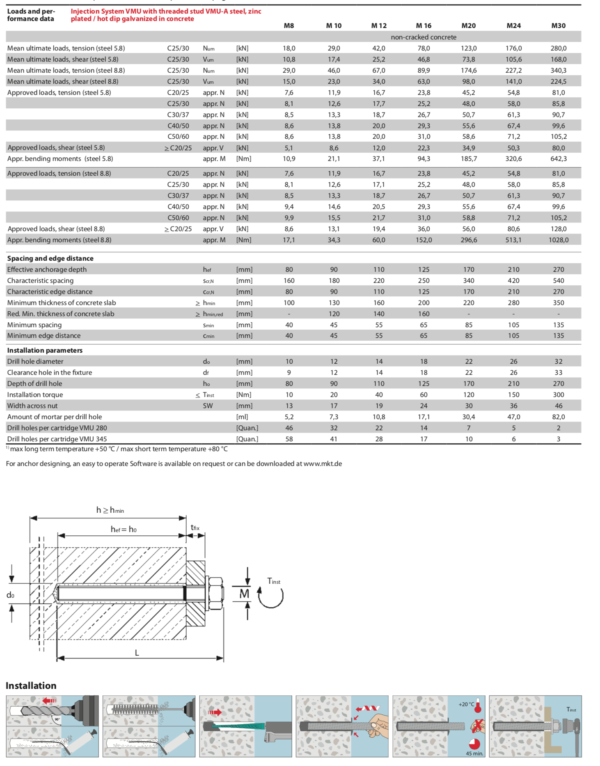

Injection System VMU

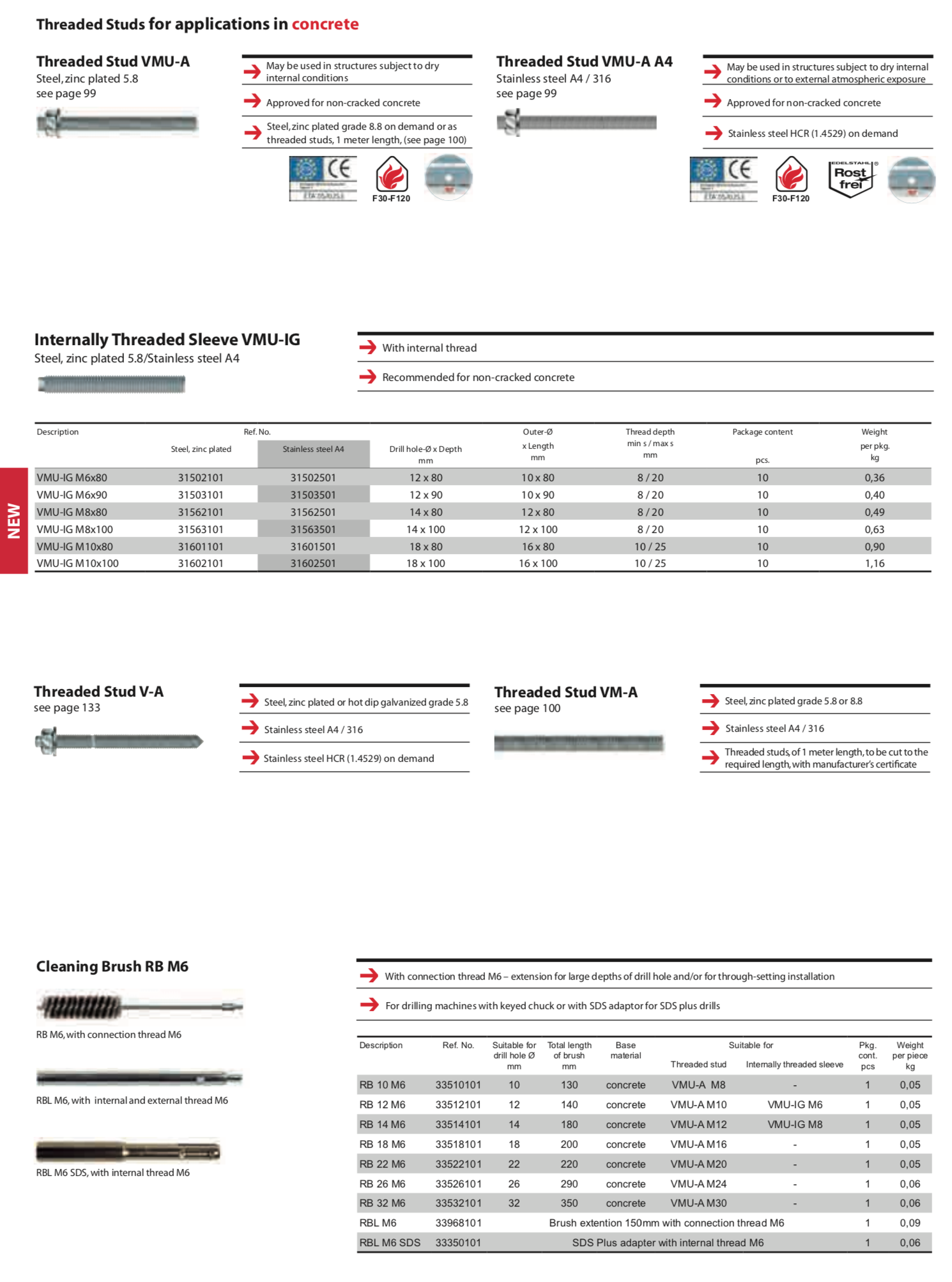

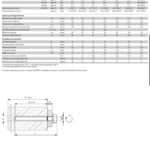

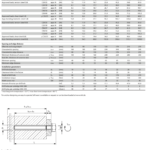

Range of loading: 7,6 kN – 105,2 kN

Concrete quality: C20/25 – C50/60

Material: Steel zinc plated, hot dip galvanized,

Stainless steel A4/316

On request: Stainless steel HCR

Description

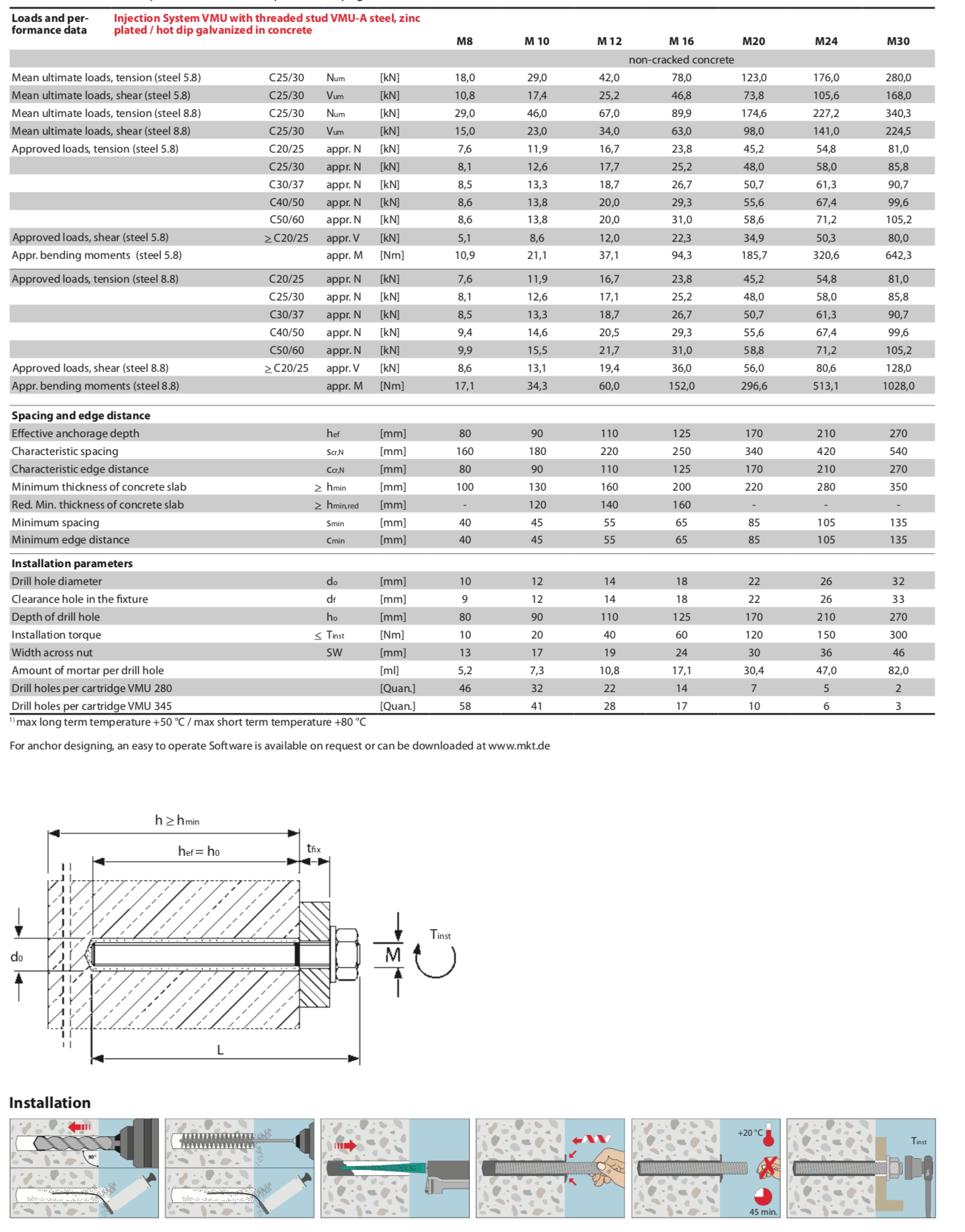

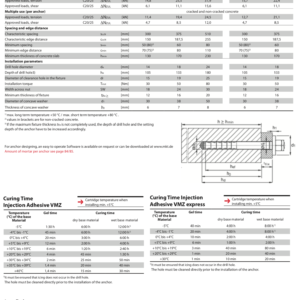

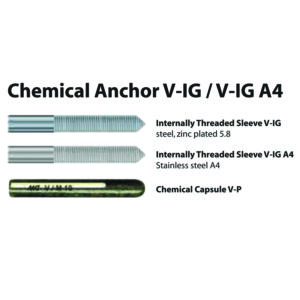

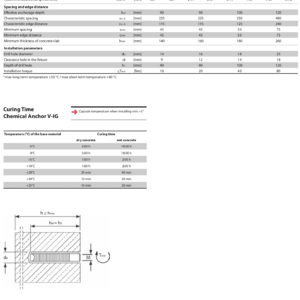

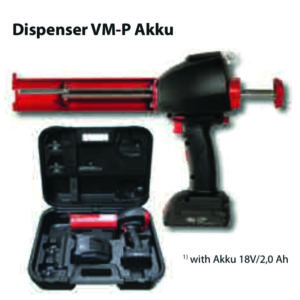

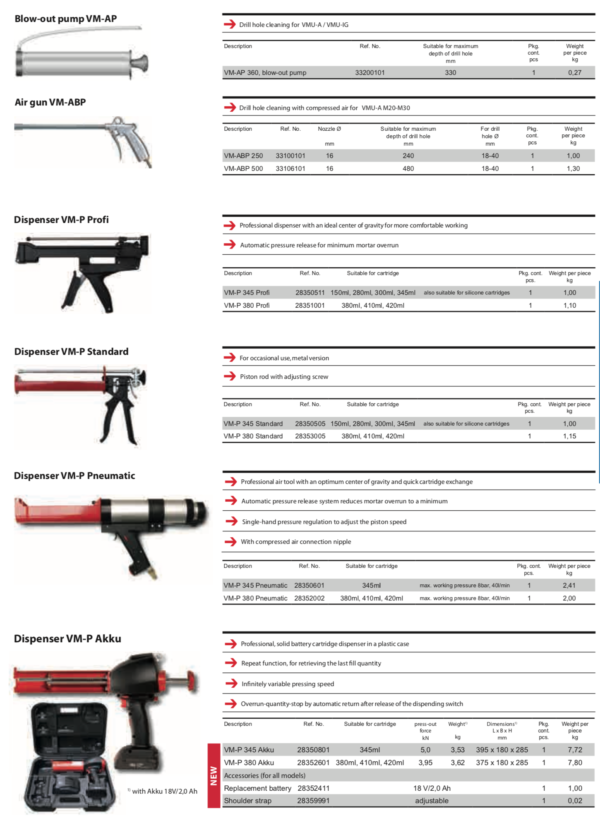

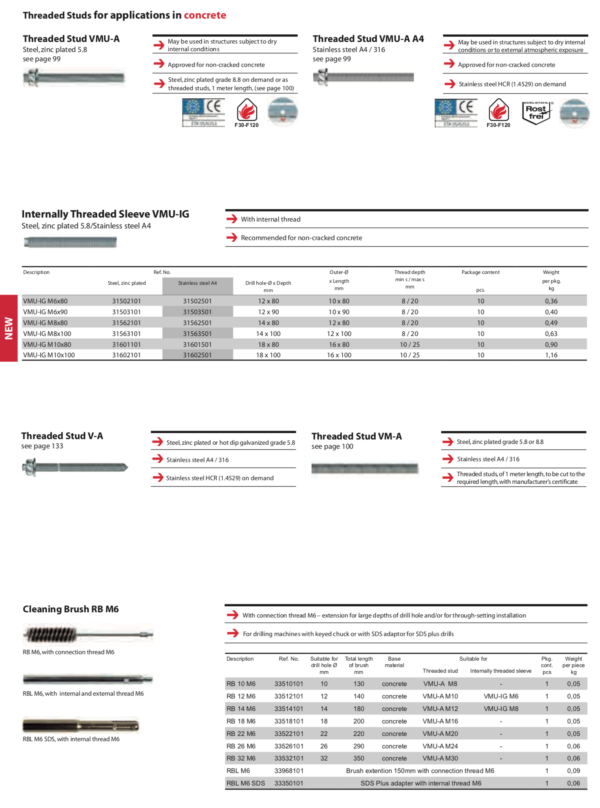

The Injection System VMU (ETA option 7) is a chemical fastening system for non-cracked concrete. It consists of a styrene-free vinyl ester resin plus an attached hardening agent contained in a cartridge to be used with a threaded stud VMU-A, an internally threaded sleeve VMU-IG, a threaded stud V-A (see pages 133) or threaded studs VM-A (see page 100). By means of the dispenser gun VM-P the components are injected through the mixer nozzle into the drill hole.The threaded stud is inserted manually into the drill hole. The hardened injection adhesive gives a secure fastening to the base material.

Advantages:

– approved in non-cracked concrete, sizes M8 to M30.

– threaded Studs V-A (pages 133) and VM-A (see page 100) are also

covered by the approval.

– approved with standard threaded studs (strength test required) – with fire test report (loads see page 153).

– no load reduction for wet concrete

– opened cartridges can be re-used with a new mixer nozzle

– VMU express with shorter curing time during the cold season

– styrene-free

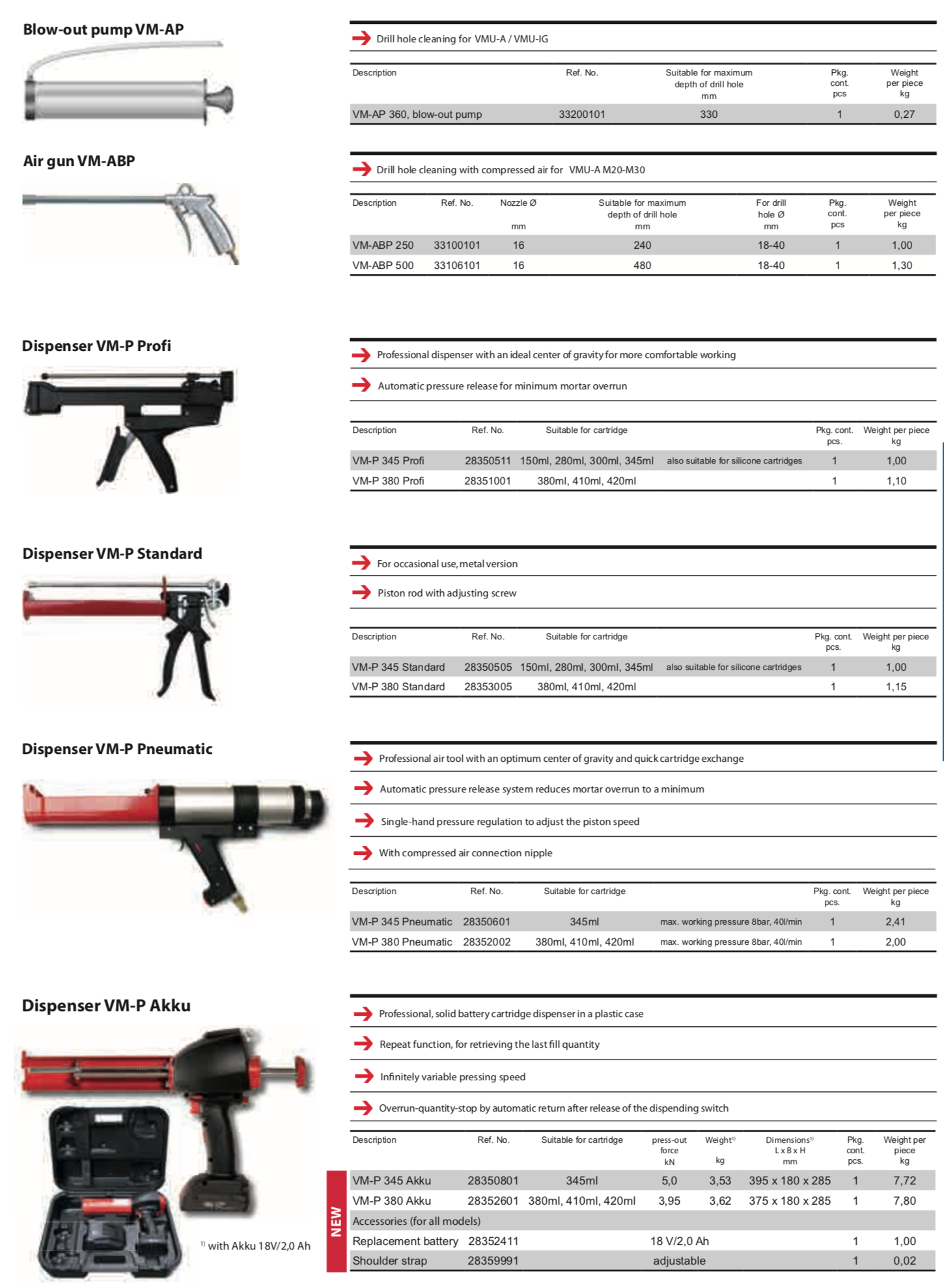

Applications

Fastenings in non-cracked concrete:

Baseplates, fastenings to walls and columns, joint tapes

- Description

Description