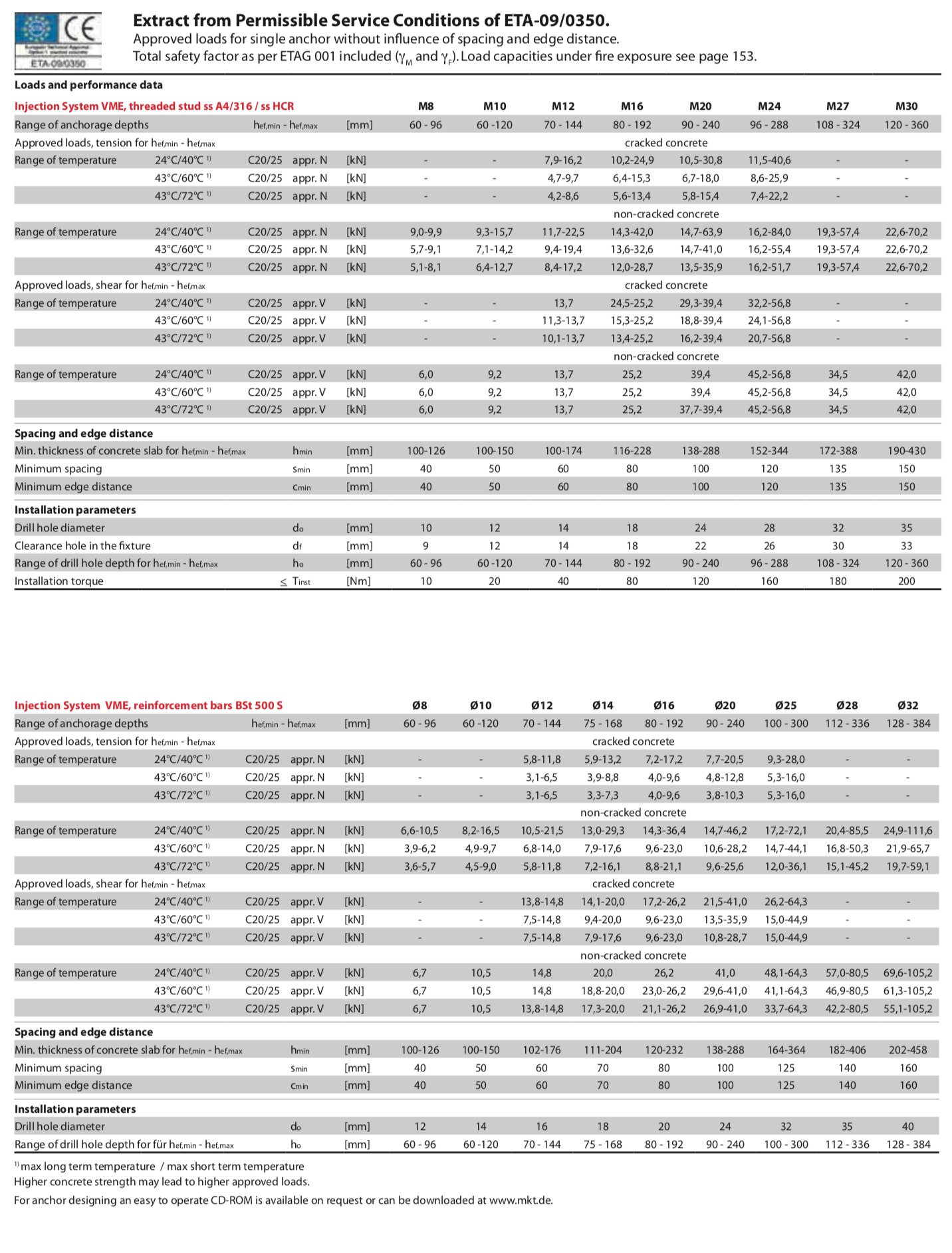

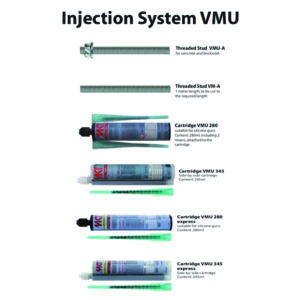

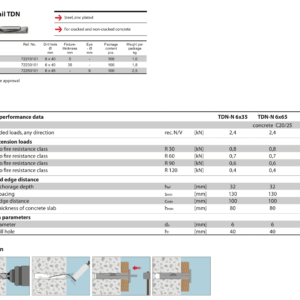

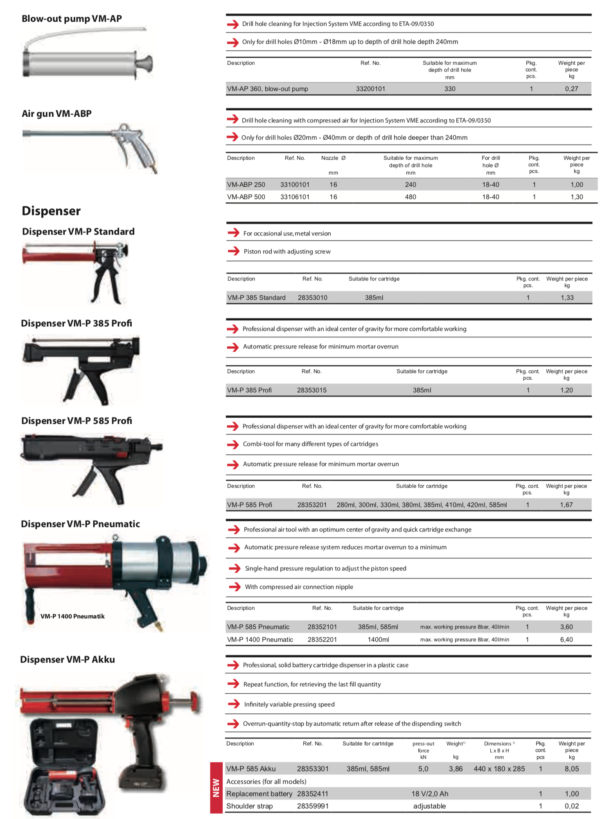

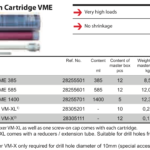

Injection System VME

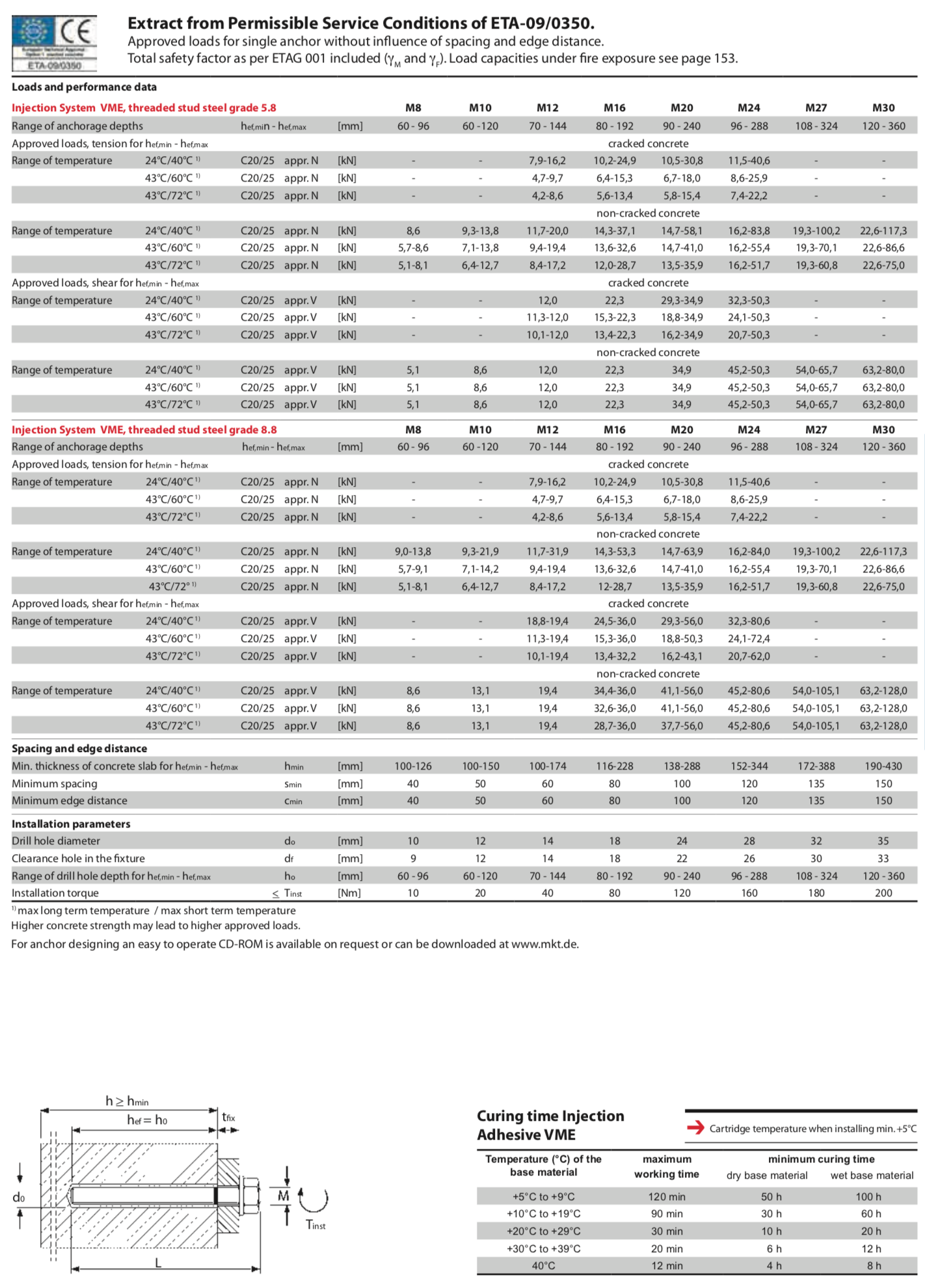

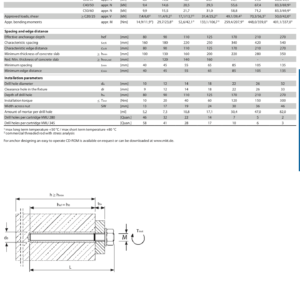

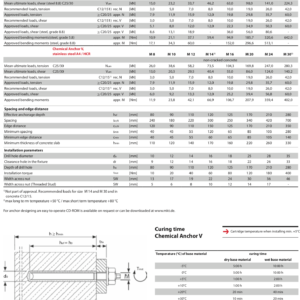

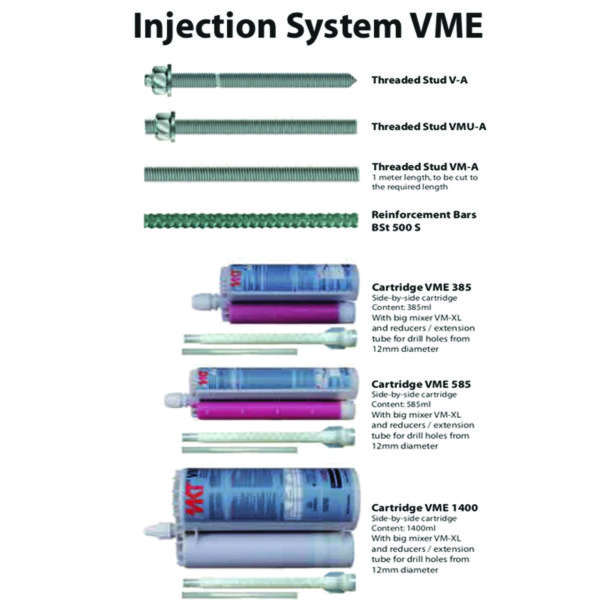

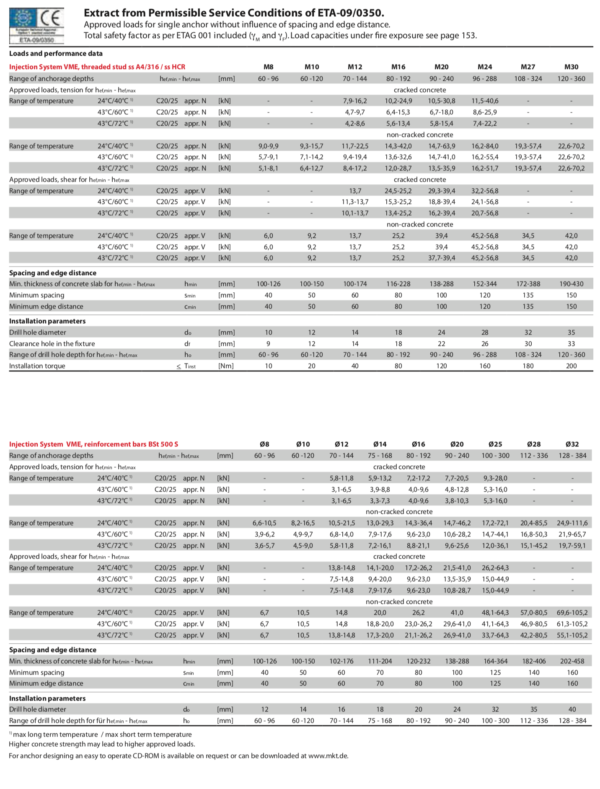

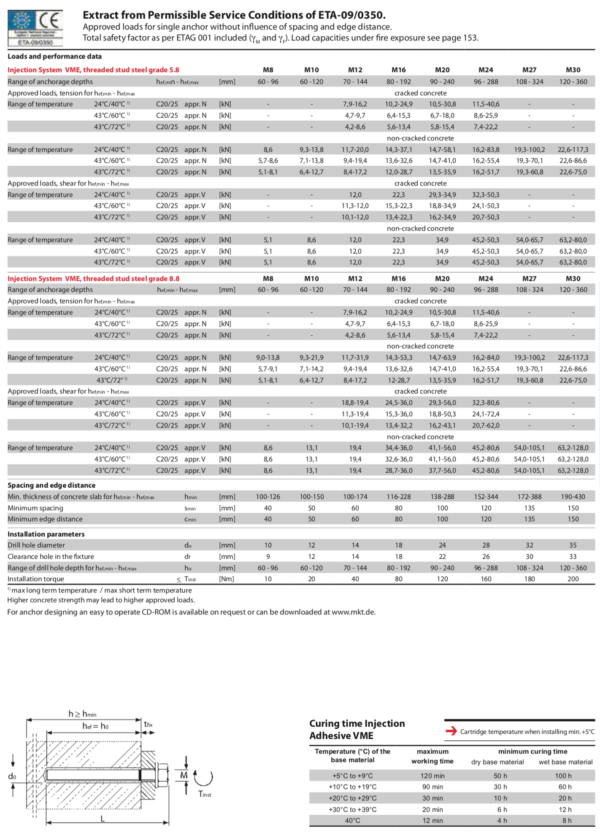

Range of loading: 3,1 -128 kN

Concrete quality: C20/25 – C50/60

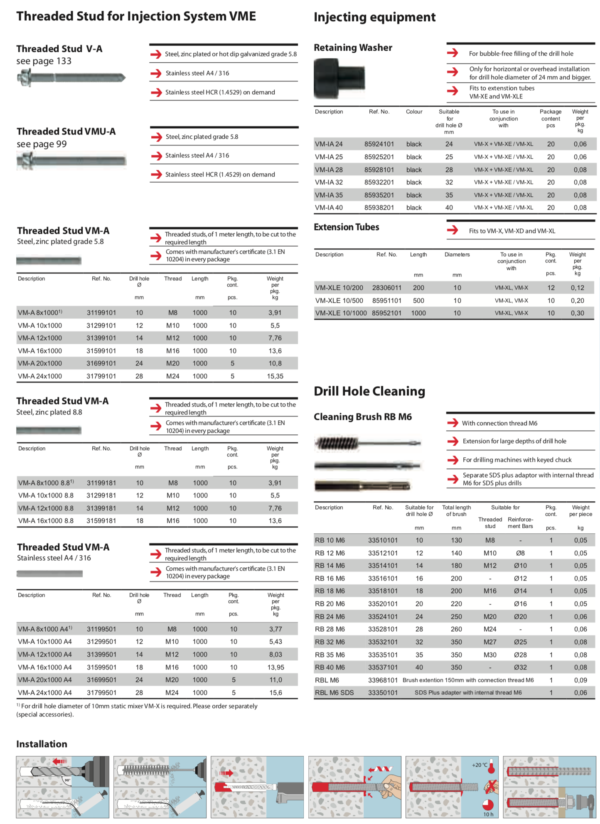

Material: Steel zinc plated, hot dip galvanized,

Stainless steel A4/316, Stainless steel HCR, BSt 500 S

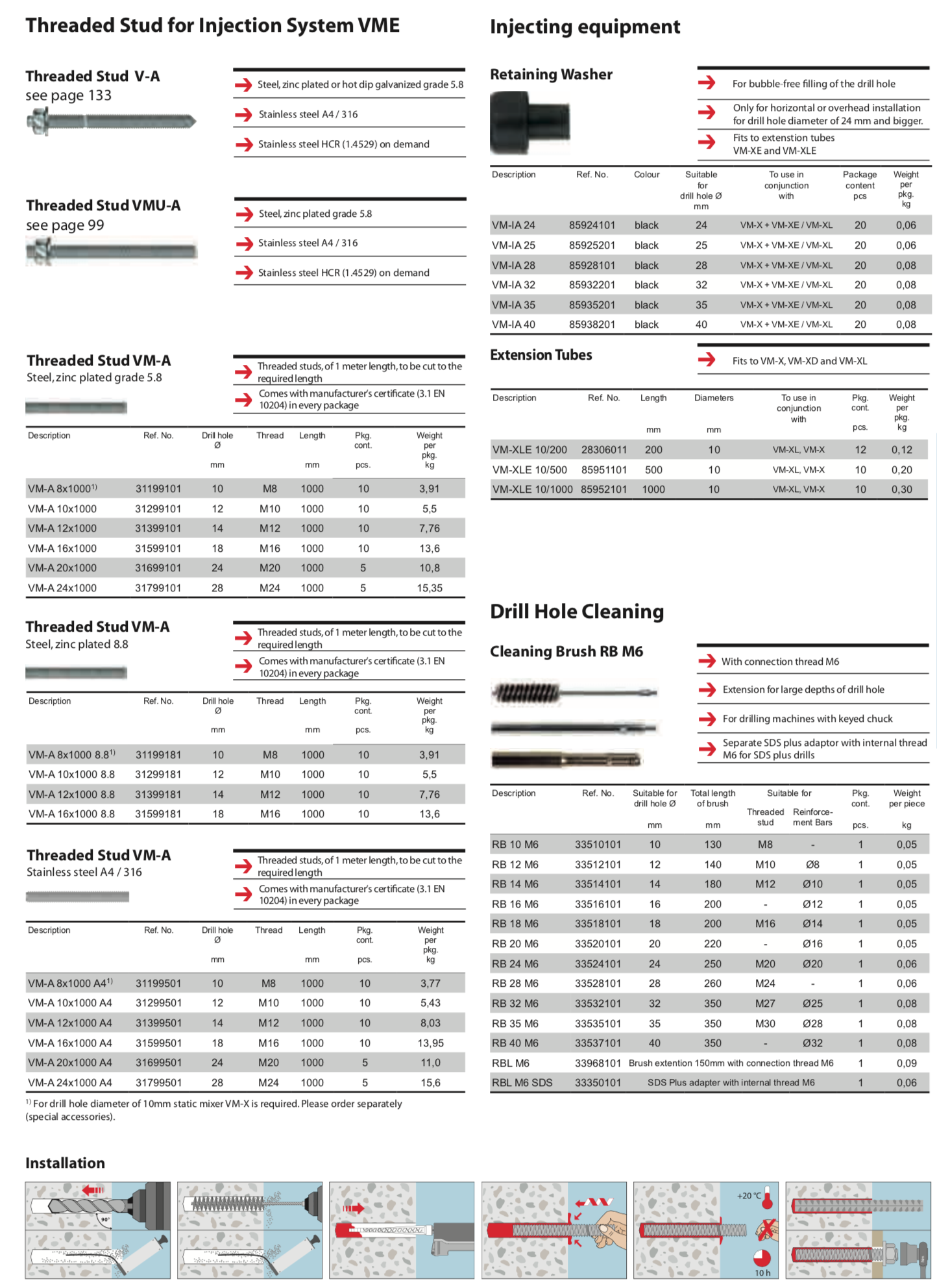

Description

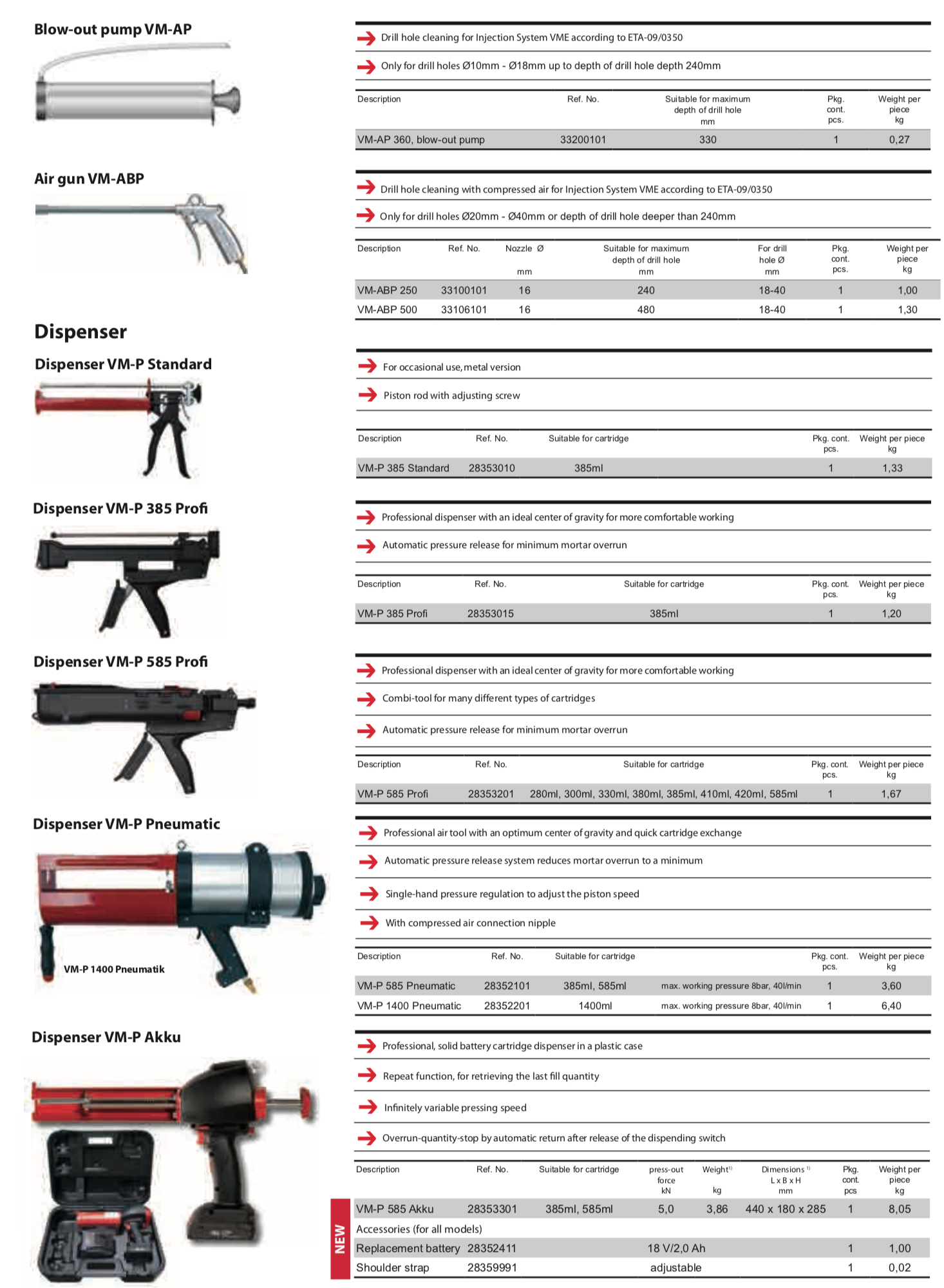

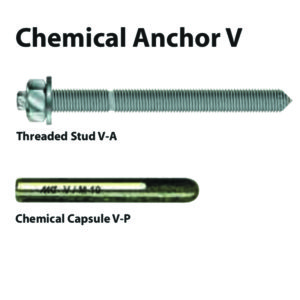

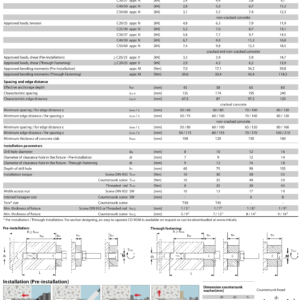

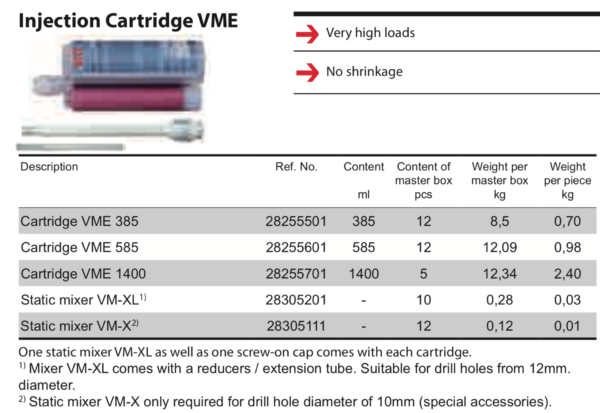

The Injection System VME is an approved system for fixings of threa- ded studs or reinforcement bars in cracked and non-cracked concrete. In the cartridge, the epoxy resin and the hardener are separated. By means of the dispenser gun VM-P the components are pushed through the mixer nozzle, activated and injected into the drill hole. The Injection System VME can be used with the threaded Studs V-A (see pages 133) and VMU-A (see page 99). It can also be used with VM-A studs, sold by meter to be cut to the required length or with standard reinforcement bars.

Applications

Fixing of rack systems, railings, steel structures, noise barriers, stairs and machines.

Subsequent closure of wall and ceiling openings, reinforcement of existing concrete structures, installation of reinforcement for the connection of the following concrete components (if the installation of reinforcement was missed or not possible because of the working process), connection of steel structures.

Advantages:

– approved in cracked and non-cracked concrete

– approved with threaded studs and reinforcement bars

– approved with standard threaded studs (strength test required)

– approved to use under seismic action according to the performance

category C1 (M12-M30) and C2 (M12-M16)

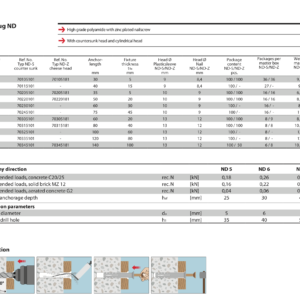

– also approved for post-installed rebar connections according to

ETA-07/0299 / Z-21.8-1872 (see page 79)

– approved for diamond coring (ETA 13/0773)

– ICC Evaluation Service listing for cracked and non-cracked concrete – variable anchorage depth for less drilling efforts

– long curing times for an economic working process with serial

installations and/or large drill holes

– suitable for dry and wet concrete and in water-filled drill holes – styrene-free

– fire test report

- Description

Description