Bitustick SR

Bitustick SR

Cross laminated blue solar reflective self adhesive waterproofing membrane

Properties

- Specially formulated for tropical climates

- Easy to handle in hot climates. Reduction of solar heat absorption by 30%

- Provides protection against water and vapor for Grades 2, 3 & 4 (BS 8102)

- Self adhesive. Requires peeling off the silicone film and applying on the surface

- Excellent adhesion to vertical and horizontal surfaces

- Excellent resistance to chlorides, sulphates, alkalis and acids

- Good resistance to tear and puncture 4 Puncture or damage of film easily detected by the oozing of the bitumen compound through the blue film

Description

Bitustick SR is a self adhesive waterproofing membrane manufactured out of a tropical grade based on polymer modified bitumen. The bitumen compound is laminated onto an impervious, non-perforated, cross laminated solar reflective HDPE film. Bitustick SR conforms to the requirements of BS 8102.

TDS For Bitustick SR

- Step by step

Substrate preparation

The surface shall be cleaned thoroughly of all contaminants like dust, traces of curing compound, oil and grease. All surface imperfections, protrusions, structurally unsound and friable concrete must be removed and repaired.

Priming

Apply Polyprime SB* (Solvent based primer) @4-6 m²/L to a clean, smooth and dry surface by brush, roller or spray. Allow the primer to dry prior to the application of the membrane. The primer promotes the adhesion between the membrane and the concrete surface.

Alignment

Start the installation of all membrane plies from the low point or drains, so that the flow of water is over or parallel to the plies, but never against the laps. All overlaps at the membrane seams shall be installed so as to have “up” slope laps over “down” slope laps. Begin membrane application by unrolling the roll of Bitustick SR membrane and aligning the side laps. Re-roll the roll halfway and stand on the unrolled portion to prevent shifting.

Application

Peel off the release film from the self adhesive side and start unrolling the membrane and press it to the surface. Smoothen out the membrane from the center to the edges in order to drive out entrapped air with a wooden press. Furthermore, an iron roller shall be used for rolling on top of the applied membrane to ensure a proper and strong adhesion of the bitumen compound with base surface. Side overlaps shall be a minimum of 50mm on the selvedge and end overlaps 100mm.

Protection

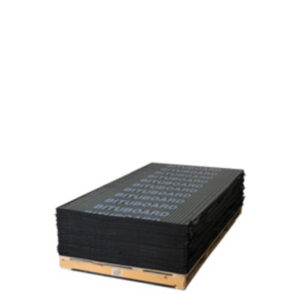

The membrane shall be protected from damage due to ongoing site activities or from aggregates during backfilling by a tough, weather, warp and rot proof asphaltic protection board (Bituboard /Bitustick R300/ Bitustick R400)*. Alternatively, on horizontal areas the membrane can also be protected by laying a cement sand screed (50mm). Bituboard can be fixed with a double sided adhesive bitumen tape (Watertite TS 15)*.