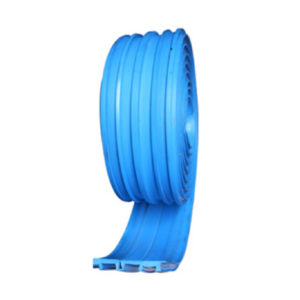

Polycrete MC

Polycrete MC

High strength free flowing micro concrete

Properties

- Rapid strength development and high ultimate strength

- Shrinkage compensated

- Minimal drying shrinkage

- Low alkali content minimizes the danger of alkali silica reaction

- Self-compacting /no honeycombing as air is displaced without need for vibration

Description

Polycrete MC is a high strength, shrinkage compensated, free flowing micro-concrete. The material is a blend of portland cement, graded aggregates, special fillers and additives. when mixed with clean water, a free flowing product is produced ideally suited to repair large volume of concrete repairs at thicknesses from 10mm to 250mm.

TDS For Polycrete MC

- Step by Step

Surface Preparation

Concrete substrate to be repaired should be sound, clean, and uncontaminated. The formwork should be rigid and tight to prevent loss of grout and have properly sealed faces to ensure that no water is absorbed from the repair material. Saw cut the extremities of the repair locations to a depth of at least 10 mm to avoid feather edging and to provide a square edge. Clean any corroded rebar by grit blasting or vigorous wire brushing. Any rebar that has lost more than 25% of its original diameter should be cut out and replaced. Prime reinforcement with Polyzinc*, zinc rich primer.

Priming

Not required, pre-wet substrate and remove any standing water before placing the formwork.

Mixing

One bag (25kg) of Polycrete MC requires 2.75 – 3.25 litre of clean potable water. In hot climates, the use of cold water (< 25°c) is recommended. Mix in a suitable size drum using an approved grout paddle at a slow speed (300/400 rpm) with a heavy-duty drill. Pour required amount of water in the mixing vessel followed by Polycrete MC. Mix for 3 minutes to get a homogeneous and consistent mix.

Placing

The mixed material should be placed within 30 minutes. It can be poured or pumped in to the repair area to fill the cavity at the required level. No vibration is required. After concrete has initially set, the surface may be finished to the desired texture.

Curing

Due to the presence of rapid drying polymers, the repaired area shall be cured in accordance with good concrete curing practice. Curing shall be done by non degradable type of curing compound or wet hessian cloth. When cured with wet hessian cloth, the area shall be covered immediately with a high density polyethyelene sheet which shall be taped to all edges.