Firestop Application Technobuilders Group Lebanon

Internal, External Cladding & Lining Products

General

The Building Code specifies the need for a fire separation system, a level of fire separation needs to be determined according to the type of structure and the uses on either side of the wall, floor or ceiling structure. Technobuilders Group is a Certified Firestop application in Lebanon.

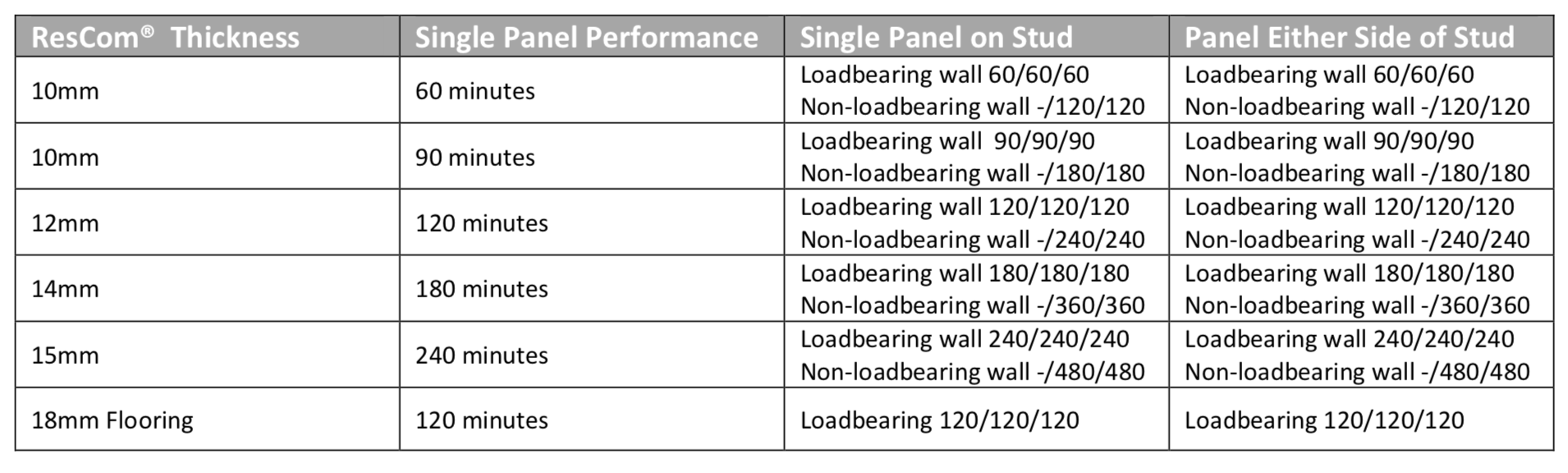

The level of fire separation is expressed by three numbers. For example, 60/60/60 represents –

- The first number indicates that for 60 minutes the wall must continue to carry the design loads. A dash here indicates a non-loadbearing wall

- The second 60 minutes is the time before the wall’s integrity is affected to allow the penetration of hot gases or flames

- The third 60 minutes indicates an insulation failure for allowing too much heat to pass through the wallRefer to the BCA to determine the fire and acoustic levels required for each application. Fire applications as follows:

When more than one board is used, such as on each side of a wall or two linings on one side of a wall, the total minutes of fire resistance is additive. This means that two 10mm boards will give at least 120 minutes of fire resistance. All gaps in fire rated structures must be filled with a recommended sealant.

Thermal and Acoustic Insulation by Technobuildersgroup Lebanon

Cavity insulation has no bearing on the fire performance of the individual ResComR panel FRL ratings. Bulk insulation may be required to achieve specified acoustic Rw+Ctr and R values in the building system. For specific performances seek direct advice from the appropriate fire and acoustic engineers.

Wall Installation

Two wall systems will be detailed – timber and steel. Timber frames are normally only suitable to a maximum of 120 minutes fire rating. The building designer must ensure that load bearing walls have been designed:

- To resist all applied loads

- To be in accordance with AS4600, AS1684 and AS1720.1, the BCA and all relevant standards

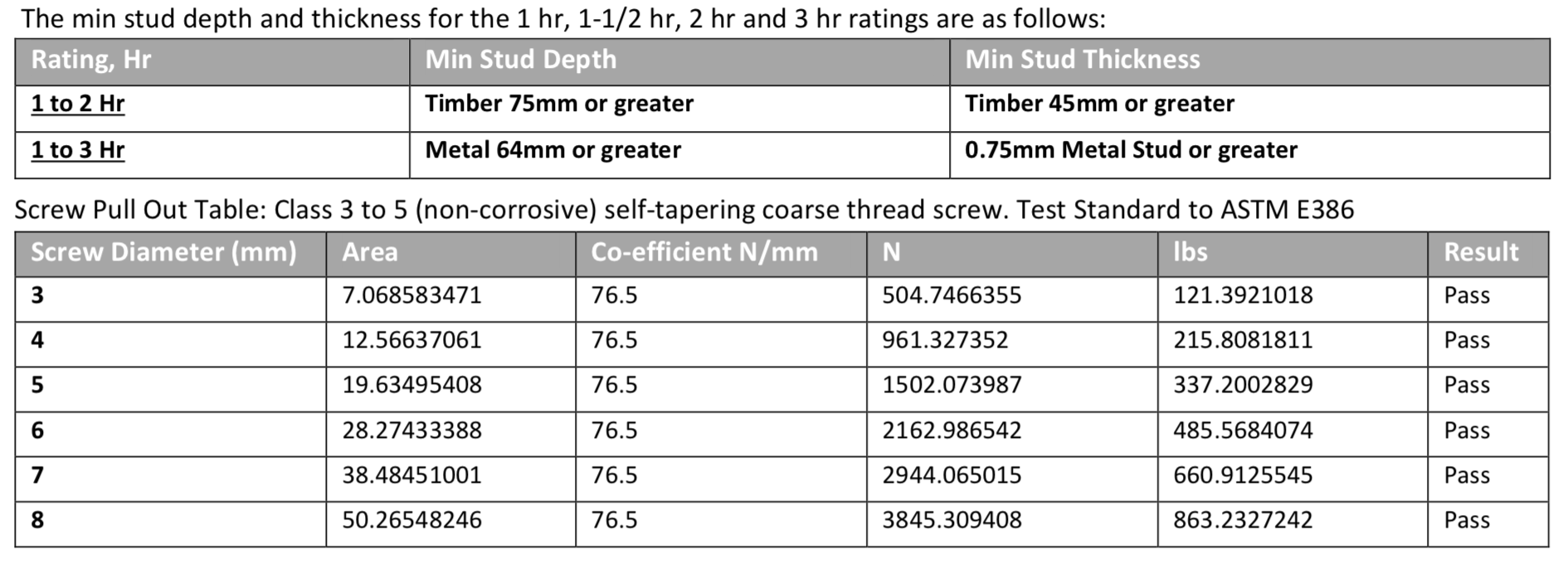

- To assume no axial strength contribution from wall linings. Some wall systems will have their axial load capacities reduced. For steel, this is due to the steel weakening at temperature. For timber, it is due to the loss of section as the timber chars.The min stud depth and thickness for the 1 hr, 1-1/2 hr, 2 hr and 3 hr ratings are as follows:

Fire Performance Detail

Fire Performance Detail

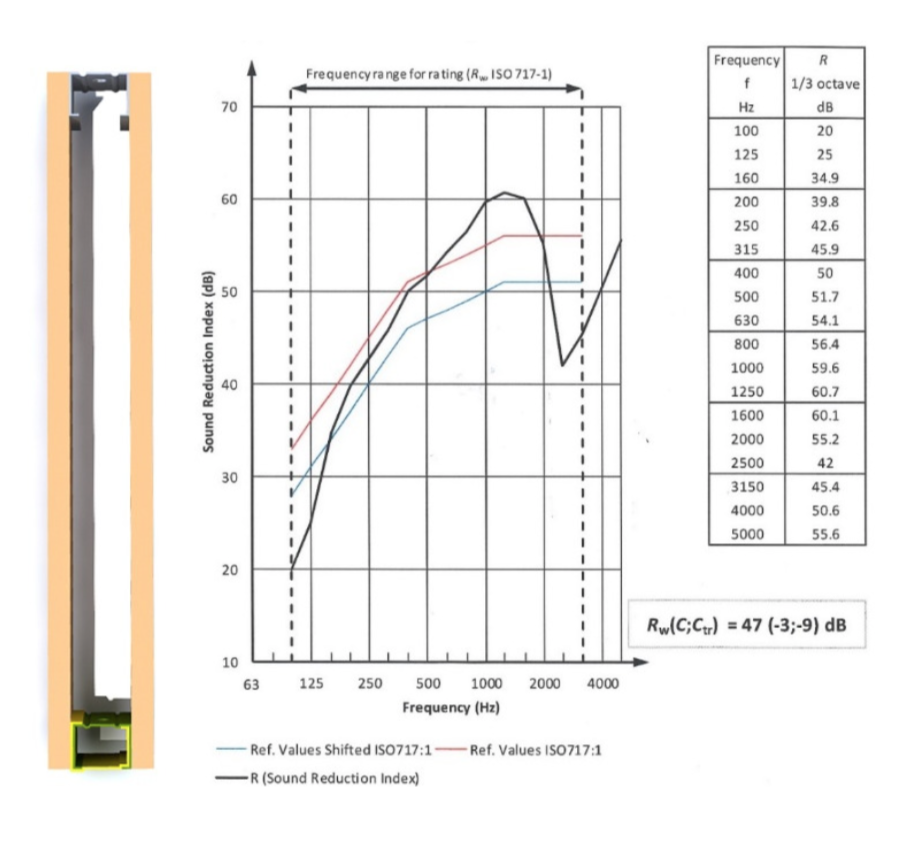

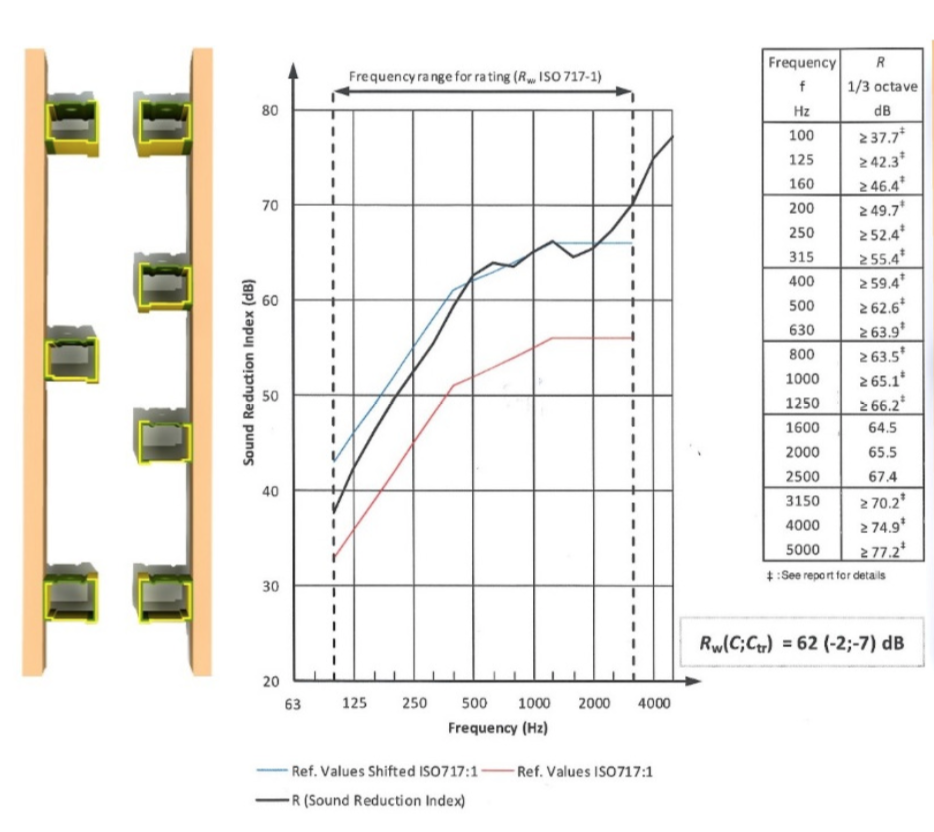

Single stud frame with75mm (1mm thick) steel studs 600mm centres and noggings at 1208.5mm from ground. 12mm ResComR board – 75mm steel studs filled with 24kg/m3 glasswool insulation – 12mm ResComR board.

Fire Performance Detail

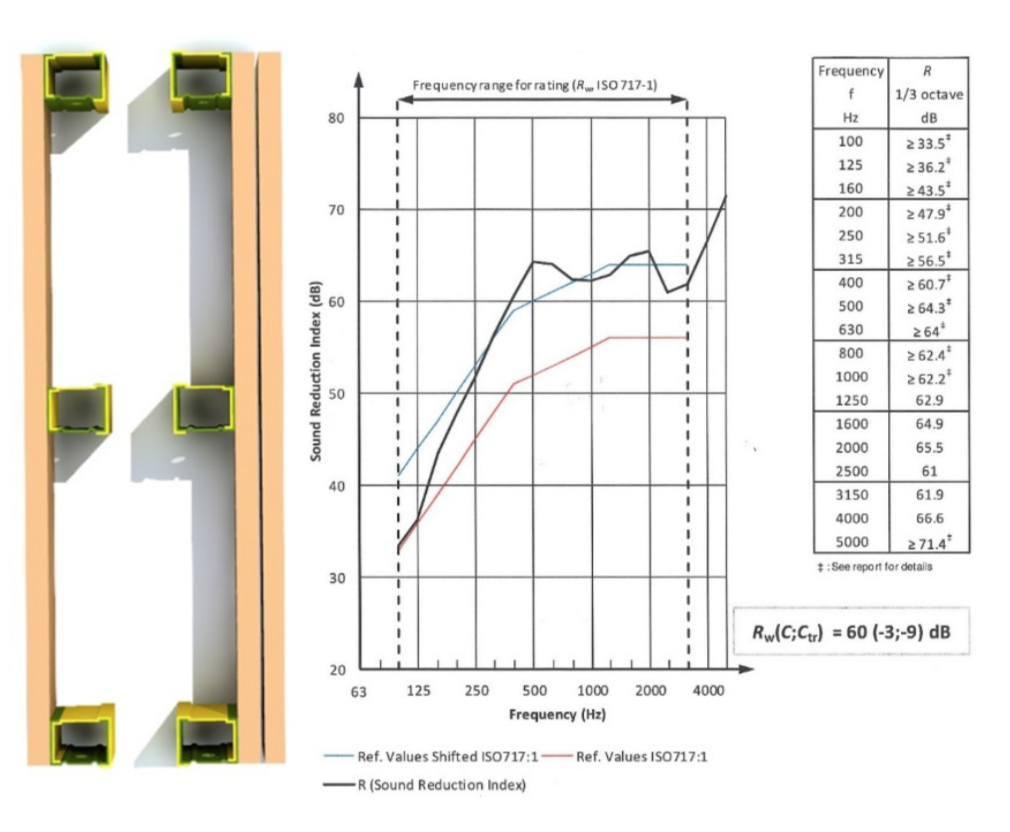

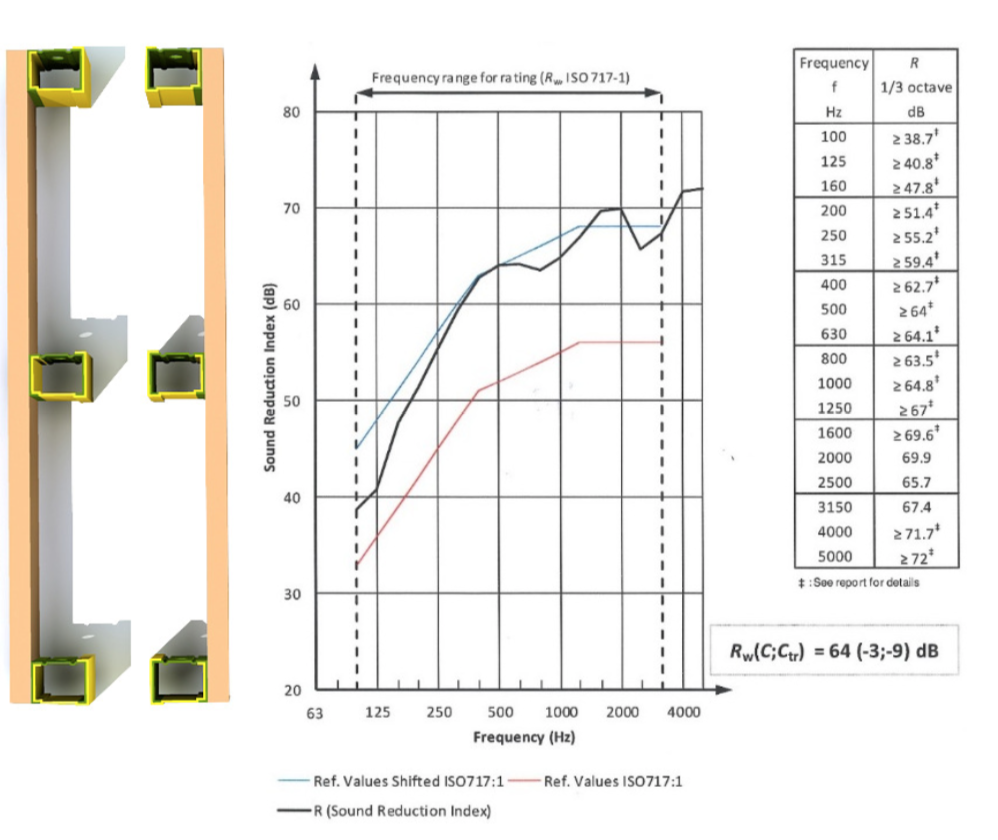

Double stud frame with75mm (1mm thick) steel studs 600mm centres and noggings at 1208.5mm from ground. 12mm ResComR board – 75mm steel studs filled with 24kg/m3 glasswool insulation – 20mm air gap – 75mm steel studs filled with 24kg/m3 glasswool insulation – 2

Fire Performance Detail

Double stud frame with75mm (1mm thick) steel studs 600mm centres and noggings at 1208.5mm from ground and 200mm (1.9mm thick) steel studs with 450mm centres.. 12mm ResComR board – 75mm steel studs filled with 24kg/m3 glasswool insulation – 25mm air gap – 200mm steel studs – 18mm ResComR board

Fire Performance Detail

Double stud frame with75mm (1mm thick) steel studs 600mm centres and noggings at 1208.5mm from ground. 12mm ResComR board – 75mm steel studs filled with 24kg/m3 glasswool insulation – 20mm air gap

– 75mm steel studs filled with 24kg/m3 glasswool insulation – 12mm ResComR board